Odour control Activated Carbon Drum Canisters

75 Drum Series

FiltaCarb vapour phase activated carbon systems provide an efficient and economical means of controlling odours and reducing VOC concentrations, corrosive gases, including Hydrogen Sulphide (H2S), and toxic vapours.

Adsorption Filtration

Air-phase adsorption systems generally use activated carbon to trap and retain molecular compounds on the contaminated airstream. Bioaction uses advanced modelling to analyse the gas composition and provide a carbon blend for performance and operational life optimisation.

Scaled Design

These units come in a range of flow and concentration capacities. Provide us with your target flow rate and gas concentrations and we will recommend the right unit for the job.

FiltaCarb 75 series carbon canisters, each containing activated carbon, are ideal for low-flow air purification in industrial and municipal applications. These budget adsorption filters are specifically designed for wastewater and acid-gas emissions but they are also suitable for a range of industrial gases.

The Bioaction FiltaCarb filter series provides total flexibility in designing a system to suit the target flow requirements and emission reduction outcomes. They are particularly well suited to:

- Sewer vents

- Wet stations

- Weir boxes

- Sewer pump stations

- Sewer wet wells

- Inlet works

- Storage Tanks

- Other acid emission sources

Drum Models

FC75

PVC drum

FC75 MS

Mild steel epoxy coated drum

FC75 SS

Stainless steel drum

- Effective treatment to remove a variety of organic contaminants and odour-causing emissions

- More than 99.5% of H2S removed

- Continuous treatment at varying flow rates and concentrations

- Low pressure drops across the filter bed

- Simple installation and operation

- Flexibility to be installed in series or multiple units in parallel

- Low cost per unit makes carbon treatment economical

- Designed for the rigors of wastewater treatment

- Rapid drum replacement when carbon is depleted

System Models

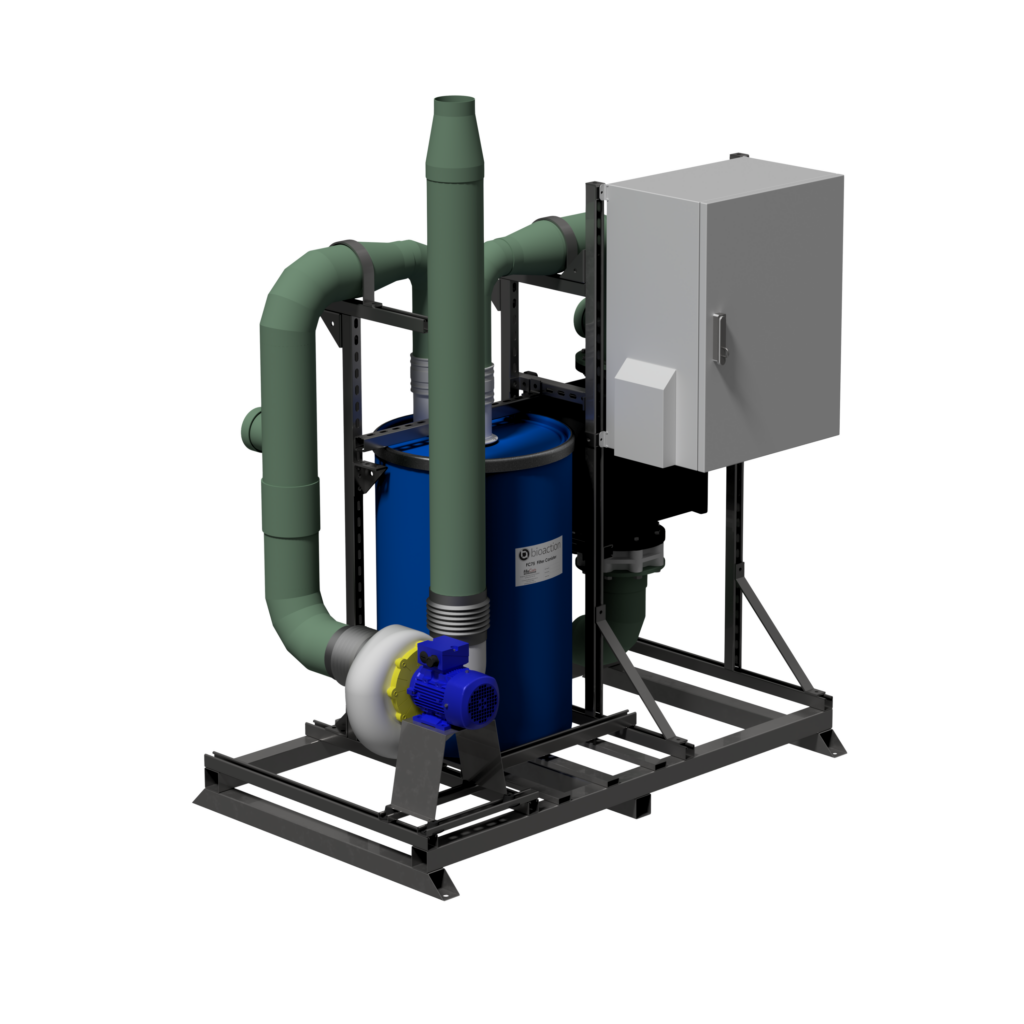

FC75 x1

- 75 L/s flow rate

- 1x Drum

- Prefilter

- Control panel

- Inlet isolation valve

- HDG skid

- Poly fan

- Negative pressure

- PVC ducting

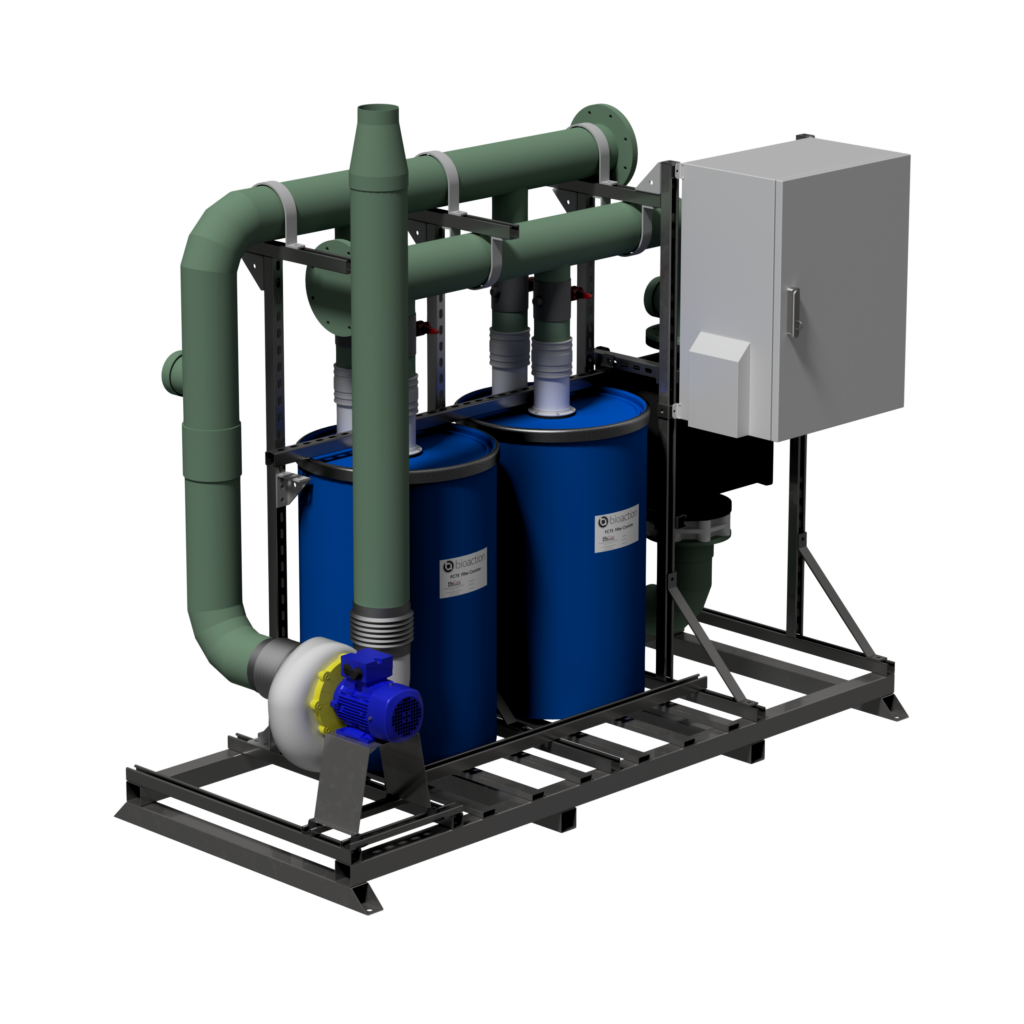

FC75 x2

- 150 L/s flow rate

- 2x Drums

- Prefilter

- Control panel

- Inlet isolation valve

- HDG skid

- Poly fan

- Negative pressure

- PVC ducting

FC75 x3

- 225 L/s flow rate

- 3x Drums

- Prefilter

- Control panel

- Inlet isolation valve

- HDG skid

- Poly fan

- Negative pressure

- PVC ducting